The Differences Concerning Cnc Machining And Vacuum Formation

So why even choose to fabricate plastic products? For starters, plastic manufacturing usually has the benefit of having fairly fast completion times, and in contrast to most materials there’s also the choice of colouring plastic prior to manufacturing, rather than after. It’s high malleability means that it possesses a reasonably low melting temperature, and it’s far more light-weight compared to numerous other materials – these two factors simplify the production process. Moreover, plastic materials are fairly inert and therefore possess higher chemical resistance. Despite these benefits, plastic material is nonetheless unsuitable for purposes that necessitate a very high physical integrity, and it is extremely vulnerable to depreciation in the long-term.

Introduction To CNC Machining

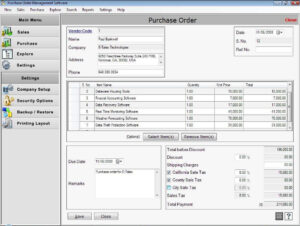

CNC machining is a computer controlled subtractive procedure, that removes material from plastic in an effort to produce the required form. The computer is high-tech, with the capability to convert a design into numbers using a computer assisted design computer software system. The figures are able to manipulate the equipment to cut the necessary shape. To setup, the machines need an intermediate step in the creation and validation of tool paths. Once the machine receives the tool paths, the subtractive procedure is launched. Once the construction is finished, the component part is washed, smoothed, and trimmed.

For lower quantity plastic component applications that call for tight tolerances and shapes which are tricky to shape, machining meets your needs. CNC machining also has minimal to medium initial costs, and can generate top of the line plastic parts with minimal completion times. Nonetheless, with increased product sophistication, the price per element climbs up. In addition, this process needs tool access considerations, and specific shapes, for instance those with curved interior channels, are near-impossible to form using CNC manufacturing.

Introduction To Vacuum Formation

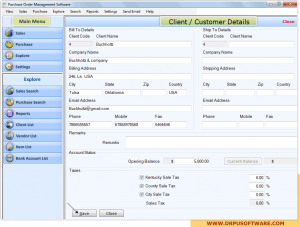

Vacuum formation is a process during which plastic material is warmed and moulded, generally working with a mould. The size and intricacy of vacuum-forming machines cover anything from affordable desktop equipment to advanced production machinery. You’ll find 1,000’s of websites with facts surrounding ‘snap frame poster’ this could be possibly one of the best sites www.display-warehouse.co.uk

It can be suitable for any project, from tailor-made designs to large-scale manufacturing, considering the large range of equipment offered and that also automation is an option if required. On the other hand, there’s little versatility in the different types of design it can create, and is unfortunately only competent to build pieces with basic geometries. In comparison with various other methods, tooling prices are minimal, since vacuum formation merely needs low forces and pressures. Generally, for smaller manufacturing sizes the moulds are constructed of 3D printed resin, or even plaster, and then for larger development sizes more durable equipment made from metal is used.

The manufacturing process begins with a sheet of plastic being clamped and heated up until the plastic becomes mouldable. The plastic will then be put into the mould and cooled, and often fans as well as other chilling techniques are implemented in an effort to speed up the cooling process. The ultimate stage entails any surplus plastic being removed.